Distinctive feature

Currently, many tunneling works involve difficult tasks such as gravel layers, sharp curves, and long-distance tunneling, and conventional lubricants alone can cause a sudden increase in the thrust force, making it impossible to handle the task. When Pipe Manicure Ⅱ is applied to the surface of a concrete pipe, it penetrates and hardens, modifying the pipe surface to a smooth PVC pipe-like surface, preventing gravel from getting caught and clay from adhering, and suppressing a sudden increase in thrust force.

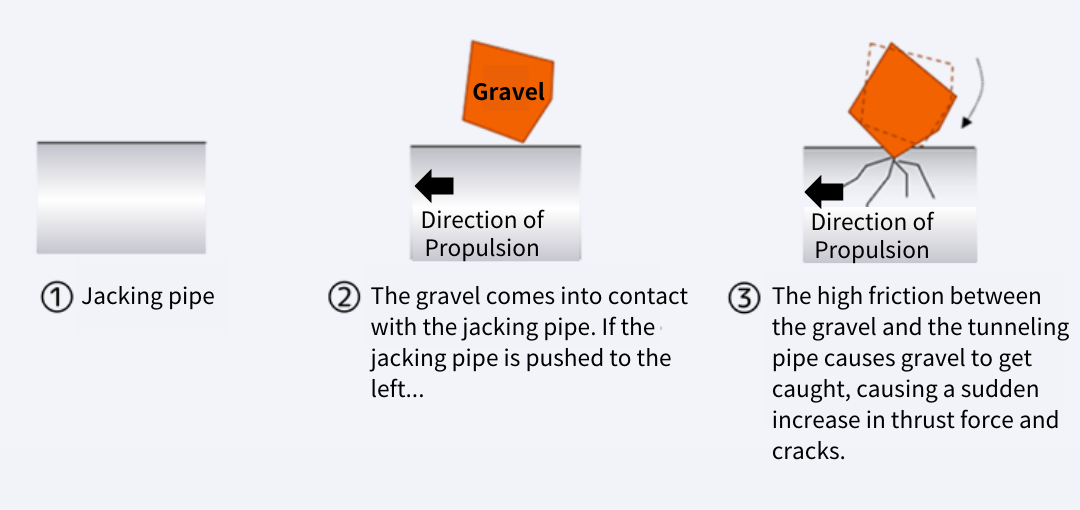

I. Previous problems

The high friction between the gravel and the tunneling pipe causes gravel to get caught, causing a sudden increase in thrust force and cracks.

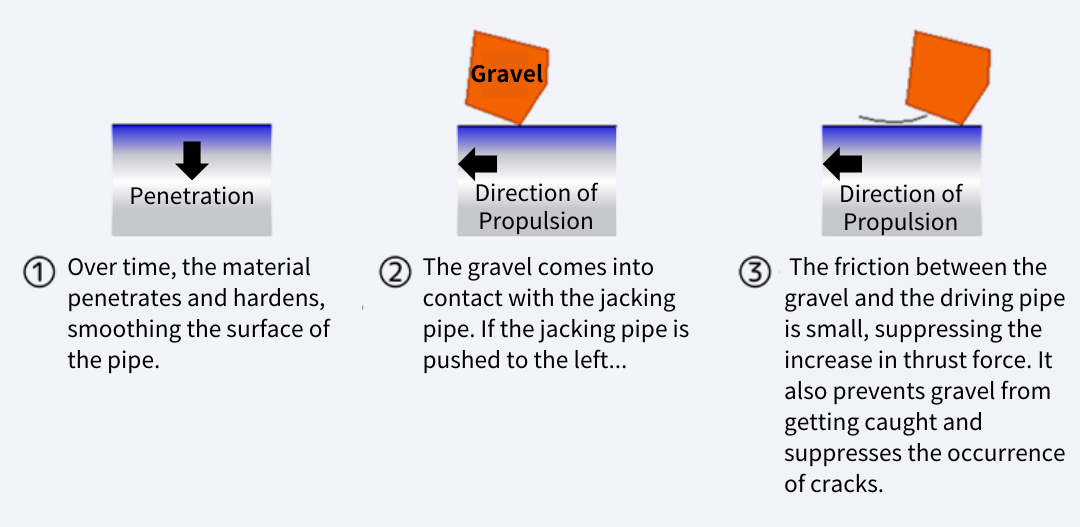

II. When using Pipe Manicure II

When this agent is applied to the jacking pipe, it penetrates and hardens, smoothing the surface of the pipe. The friction between the gravel and the driving pipe is small, suppressing the increase in thrust force. It also prevents gravel from getting caught and suppresses the occurrence of cracks.

Application site

- Caisson

Explanation video

Packaging Type

| Net Weight | 5kg |

|---|---|

| Package Style | Poly Can |

| Example of Coating Area | 1㎡/0.045L×4.5L=Approx. 100㎡ |

How to use

- When the surface of the concrete pipe is dry, apply the product evenly to the surface of the pipe using a sponge brush or similar tool.

- Let it dry for about 3 hours and it’s ready. No need to apply more coats.

- After application, the pipe surface will become slippery, so do not stand on it.

- This agent penetrates into the pores of concrete, modifying the surface and exerting its effect. If you apply it thicker than necessary, the excess nail polish will dry and deposit on the surface as a thin white film. Even if this film peels off, it will not affect the effectiveness of the Pipe Manicure Ⅱ.

- If any medicine is left over, return it to the original container, seal it, and store it in a dark place.

Major construction projects

【By type of work】 Pipe jacking ・ Caisson

#1 Construction of S-shaped curve in dry gravel layer

| Pipe diameter | φ800mm |

|---|---|

| Extension | 380m |

| Soil type | Anhydrous gravel |

| Construction method | Slurry type pipe jacking method |

#2 Large diameter long distance construction

| Pipe diameter | φ800mm |

|---|---|

| Extension | 380m |

| Soil type | Anhydrous gravel |

| Construction method | Slurry type pipe jacking method |

#3 Ultra-large diameter construction

| Pipe diameter | φ3500mm |

|---|---|

| Extension | 200m |

| Soil type | Sand silt |

| Construction method | Earth pressure type pipe jacking method |

#4 Long-distance horizontal vertical curve construction

| Pipe diameter | φ800mm |

|---|---|

| Extension | 890m |

| Soil type | Gravel |

| Construction method | High-density slurry type pipe jacking method |

#5 Ultra-large diameter BOX construction

| Pipe diameter | □5m×6m |

|---|---|

| Extension | 32m |

| Soil type | Silt |

| Construction method | Earth pressure type pipe jacking method |

#6 Caisson construction

| Pipe diameter | □10m×6m |

|---|---|

| Extension | 22m |

| Soil type | sand |

| Construction method | Pneumatic caisson |