Distinctive feature

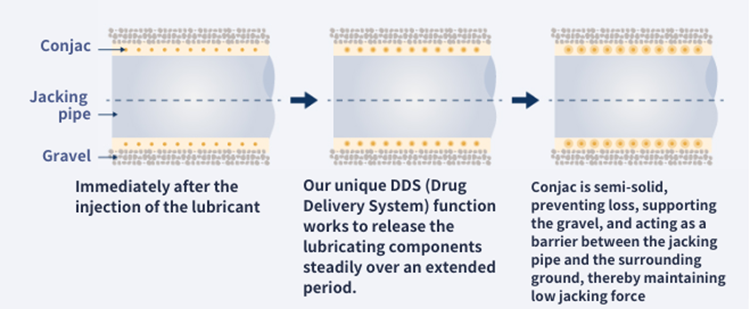

This agent is a filler with a unique DDS (Drug Delivery System) function that steadily releases slippery components over an extended period. It enables long-term maintenance of low thrust, not only in water-bearing layers but also in anhydrous layers, which have previously been considered difficult to manage.

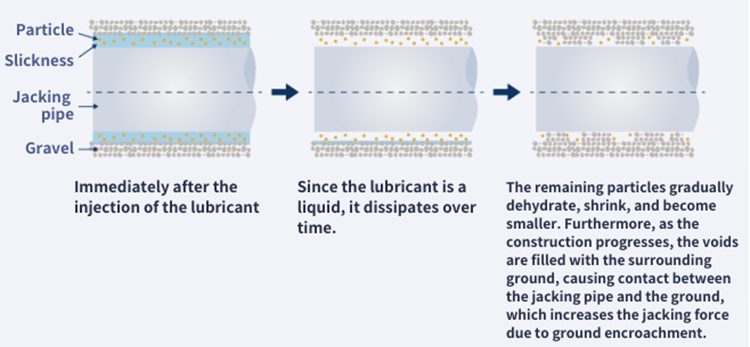

Ⅰ. Thrust increase mechanism of general lubricants

Ⅱ. The thrust reduction mechanism of Conjac

Application site

Explanation video

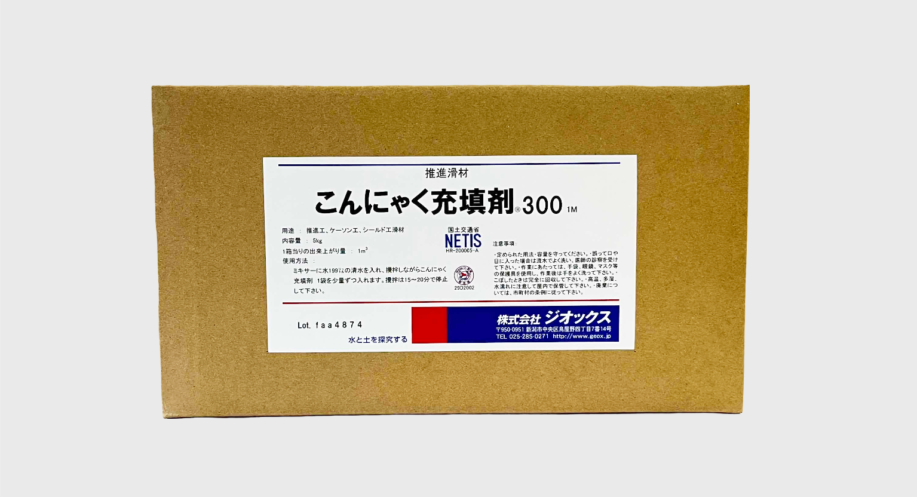

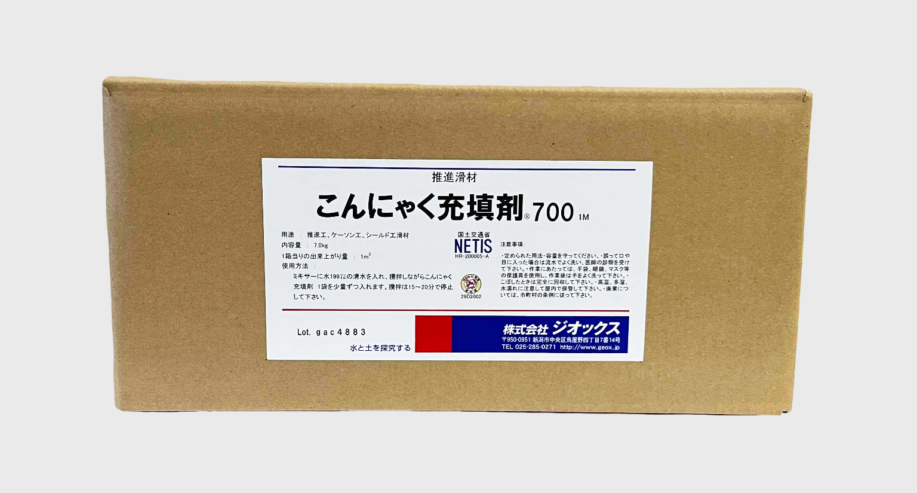

Packaging Type

| Conjac 300 | Conjac 700 | |

|---|---|---|

| Net Weight | 6 kg | 9 kg |

| Package Style | 1.2 kg per bag × 5 bags, packed in a cardboard box | 1.8 kg per bag × 5 bags, packed in a cardboard box |

| Finished Quantity | 1,000 L | 1,000 L |

| Packing Style | Cardboard box | Cardboard box |

Applicable site

| Caliber | Distance | Soil type | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Small | Middle | Big | Short | Middle | Long | Clay | Sand | Gravel | |

| Conjac 300 | ○ | ○ | △ | ○ | ○ | △ | ○ | ○ | △ |

| Conjac 700 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

◎Excellent, ○Good, △Fair

How to use

- Pour 199 L of clean water into the mixer.

- While stirring the mixer, gradually add one bag of Conjac in small amounts.

Stop stirring after 15 to 20 minutes. (Do not stir for more than 20 minutes.) - Prolonged exposure to direct sunlight may affect the lubricating effect, so it is recommended to cover the mixer with a lid.

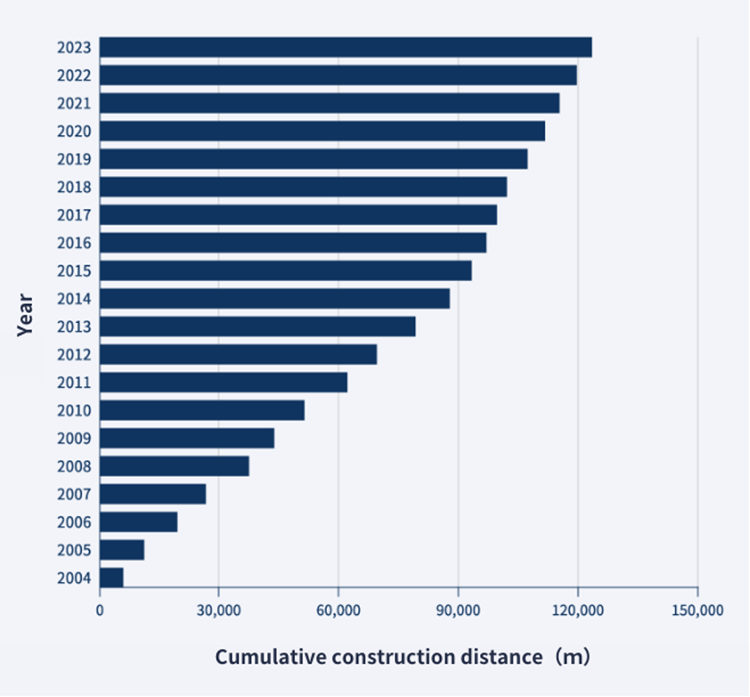

Cumulative construction distance

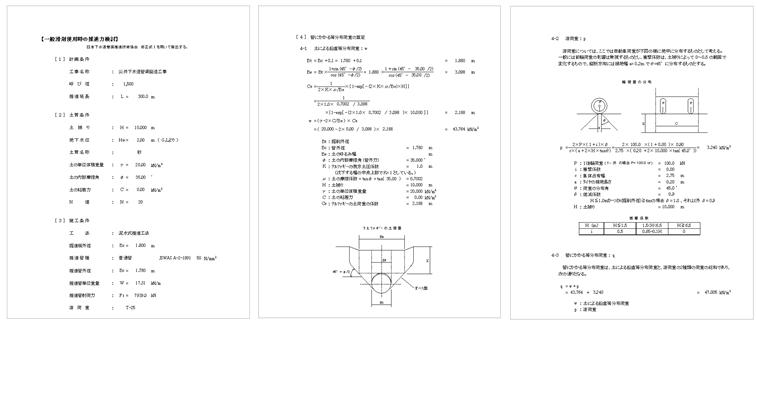

Calculation of Jacking Force

We calculate the jacking force at your site using the jacking force reduction coefficient derived from the construction performance of the Conjac. Please feel free to consult us first.

Example of Jacking Force Calculation for the Slurry-Type Pipe Jacking Method

Major construction projects

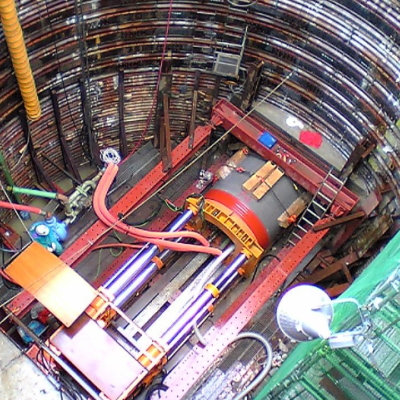

【By type of work】 Pipe jacking ・ Caisson

#1 Construction of an S-shaped curve in a dry gravel layer

| Pipe diameter | φ800 mm |

|---|---|

| Extension | 380 m |

| Soil type | Anhydrous gravel |

| Construction method | Slurry type pipe jacking method |

#2 Large diameter long distance construction

| Pipe diameter | φ3000 mm |

|---|---|

| Extension | 500 m |

| Soil type | Sand |

| Construction method | Slurry type pipe jacking method |

#3 Ultra-large diameter construction

| Pipe diameter | φ3500 mm |

|---|---|

| Extension | 200 m |

| Soil type | Sand silt |

| Construction method | Earth pressure type pipe jacking method |

#4 Long-distance construction near the coast

| Pipe diameter | φ1000 mm |

|---|---|

| Extension | 480 m |

| Soil type | Sand |

| Construction method | Slurry type pipe jacking method |

#5 Ultra-large diameter BOX construction

| Pipe diameter | □5 m×6 m |

|---|---|

| Extension | 22 m |

| Soil type | Sand |

| Construction method | Pneumatic caisson |

Frequently asked questions

- Is it effective even in a dry gravel layer (a stratum without groundwater where the lubricant is absorbed into the ground and lost)?

- It enables long-term maintenance of low jacking force not only in aquifers but also in dry gravel layers, which have been considered challenging until now.

- The groundwater has a high salinity concentration. Would this still be acceptable?

- Please send 1–2 liters of groundwater to our company before starting construction. We will propose the most suitable lubricant for each site.